Introduction

Electric screwdrivers have become essential tools for modern households and workshops. Because they combine high efficiency with effort-saving operation, they are widely used in home repairs, DIY crafts, and appliance assembly. However, many users overlook a critical fact: proper usage and regular maintenance directly affect both performance and service life. If a screwdriver is misused or poorly maintained, it can overheat, wear down faster, or even fail during important tasks. Therefore, learning how to use and care for an electric screwdriver not only improves work efficiency but also ensures long-term reliability.

Daily Usage Tips

1. Bit Selection and Installation

The performance of an electric screwdriver begins with choosing the right bit. Because screws come in different shapes—cross, flat-head, or hexagonal—selecting a perfectly matched bit prevents thread slippage and damage.

When installing, insert the bit vertically into the chuck until you hear a clear "click". This indicates it is securely locked. If the chuck feels loose, clean internal debris or replace the chuck to avoid slipping during operation.

Various drill bits

2. Torque and Speed Adjustment

Different materials require different torque levels. For this reason:

· Low torque (1–3 settings): Best for delicate electronics such as mobile phones, laptops, or soft materials like wood and plastic.

· High torque (7–10 settings): Suitable for heavy-duty tasks, including metal furniture, windows, and doors where stronger fastening force is necessary.

Adjusting torque and speed

A key rule: never shift directly from the lowest gear to the highest gear, because sudden jumps may cause the clutch's steel balls to fall out, damaging the tool.

A key rule: never shift directly from the lowest gear to the highest gear, because sudden jumps may cause the clutch's steel balls to fall out, damaging the tool.

3. Safe Operation Practices

Because safety and precision go hand in hand, keep the screwdriver bit perpendicular (90°) to the screw at all times. Tilting increases the risk of slippage.

If you hear a repetitive "click-click" sound, this means the torque protection has been triggered—stop immediately to avoid over-tightening. For added protection, wear goggles and secure long hair or loose clothing to prevent accidents.

Image source: Using Cordless Screwdriver for Anything + Practical Tips

Maintenance and Care

1. Cleaning and Dust Prevention

Dust and debris can reduce efficiency over time. After each use, wipe the outer casing and bit with a dry cloth. In dusty environments, use a soft brush to clean ventilation holes. For deeper cleaning, blow compressed air into the chuck and gaps to prevent clogging and overheating.

2. Lubrication Maintenance

Because gears and bearings endure constant friction, apply a thin layer of silicone-based grease once a month. For the chuck, add a small amount of lubricating oil such as WD-40, but avoid excessive amounts that could seep into the motor.

3. Battery and Power Management

Cordless models: Maintain about 50% charge if unused for long periods. Recharge and discharge every 3 months to extend battery life. Avoid hot or humid storage areas.

Wired models: Regularly inspect power cords. Always hold the plug base when unplugging instead of pulling on the cable, which may cause damage.

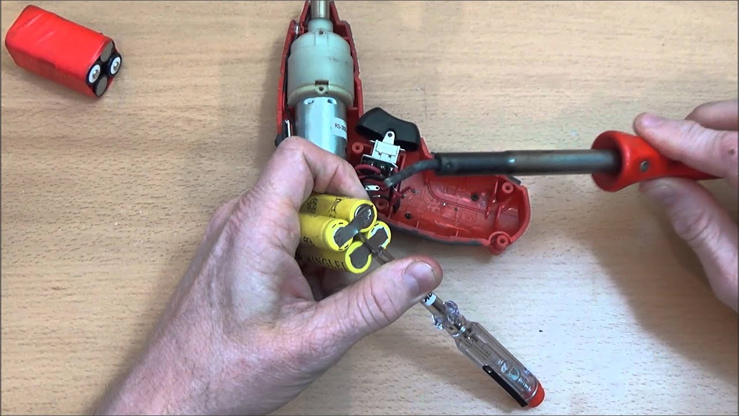

4. Inspection of Key Components

For brushed motors, check carbon brushes every 1–3 months. Once they wear down to one-third of their length, replace them in pairs and clean carbon dust from the rotor. Worn or deformed bits should also be replaced promptly to maintain torque accuracy.

Electric Screwdriver Inspection and Repair

Troubleshooting Common Problems

Even with proper care, electric screwdrivers may occasionally malfunction. Here are common issues and solutions:

· Doesn't start: Check the battery charge or power supply. For brushed motors, replace worn carbon brushes.

· Bit slipping: Replace the bit or clean debris inside the chuck.

· Unusual noise: Stop immediately and check whether gears need lubrication or bearings are damaged.

· Overheating: Pause for 15–30 minutes and clean ventilation holes. Avoid continuous operation longer than 30 minutes.

Long-Term Storage Tips

When storing an electric screwdriver, place it in a dry, well-ventilated environment, away from heat and humidity. Remove the battery from cordless models and store bits separately. For corded models, neatly wind the cable to prevent bending or damage.

Electric screwdriver storage case

Conclusion

Because electric screwdrivers combine speed, precision, and versatility, they have become indispensable for both professionals and DIY enthusiasts. However, how you use and maintain them determines how long they last. By following proper bit selection, torque adjustment, cleaning, lubrication, and storage practices, you can ensure your screwdriver remains efficient and reliable for years.

If you're looking for the best electric screwdriver for home improvement projects or professional assembly work, investing in proper care is just as important as investing in the tool itself.