Introduction

Hardware tools play a crucial role in industrial manufacturing, construction, home maintenance, and everyday life. Because they are made from durable metals like iron, steel, aluminum, and various alloys through processes such as forging, rolling, and cutting, they can withstand repeated use and high-stress operations. Choosing the right tool for a specific task is essential for efficiency, safety, and longevity.

Depending on their function, application, and material, hardware tools can be broadly classified into several categories, each designed to meet particular operational needs.

Major Hardware Tools Classified by Application

Manual Tools

Manual hand tools, such as wrenches, pliers, hammers, and screwdrivers, are widely used for maintenance, assembly, and repair tasks. Because they rely on human force rather than electricity, they are ideal for precision work or environments without power access.

Image source: Top 15 Hand Tool Manufacturers in the Industry

Power Tools

Power tools, including electric drills, angle grinders, and electric screwdrivers, offer higher efficiency and speed. Because they are powered by electricity, they can handle repetitive tasks or heavy-duty operations more effectively than manual tools.

Image source: How to Choose the Correct Power Tool

Pneumatic Tools

Tools like pneumatic wrenches and nail guns operate using compressed air. Because air-driven tools can deliver high torque without heavy mechanical components, they are often preferred in automotive maintenance and industrial production lines.

Image source: Different Types of Pneumatic Tools and Their Uses

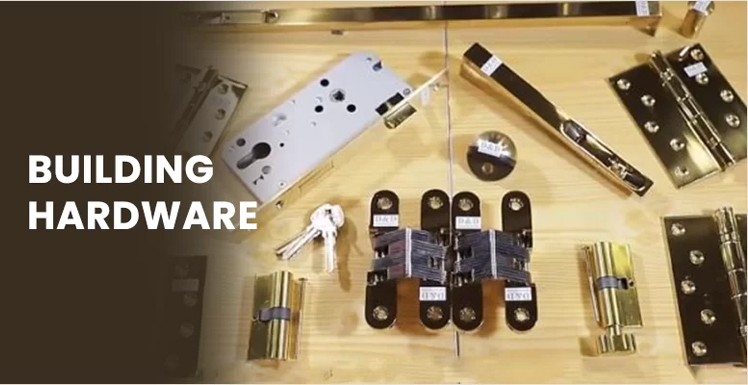

Building Hardware

Building hardware includes locks, hinges, door and window accessories, and pipe fittings. Because buildings require both structural integrity and functionality, selecting appropriate hardware ensures safety and long-term reliability in construction and decoration projects.

Building Hardware

Daily-Use Hardware

Daily-use tools, such as scissors, knives, and nail clippers, are designed for household and personal tasks. Because these tools are used frequently, quality and ergonomics directly affect convenience and safety.

Household nail clippers and scissors set

Automotive Maintenance Tools

Tools like jacks, tire wrenches, and diagnostic instruments are specifically designed for vehicle maintenance. Because cars involve precise mechanical systems, reliable hardware tools are essential to prevent damage during repair and servicing.

Jack, tire wrench and other auto repair tools

Measuring Instruments

Measuring tools, such as tape measures, vernier calipers, and levels, provide precise readings necessary for both industrial and domestic applications. Because accurate measurements influence the quality of work, these tools are indispensable in engineering, construction, and DIY projects.

Image source: How to choose your measurement tools?

Major Hardware Tools Classified by Function

Cutting Tools

Cutting tools, including saw blades, cutters, and scissors, are used to shape or segment materials like wood, metal, and plastic. Because material properties vary, choosing the right cutting tool ensures efficiency and prevents damage.

Different types of cutting tools

Fastening Tools

Screwdrivers, wrenches, and socket sets are used to fasten or loosen screws and nuts. Because fasteners hold structures together, using high-quality fastening tools prevents stripping and ensures stability.

Image source: 15 Essential Types of Wrenches Every Homeowner Should Know

Grinding and Polishing Tools

Tools like grinding wheels, polishing machines, and files refine surfaces and improve finishes. Because smooth surfaces reduce friction and wear, these tools are critical in metalworking and woodworking.

Polishing tool for cars

Lifting Tools

Hand chain hoists and pulley blocks allow for safe lifting of heavy objects. Because manual handling of heavy loads can be dangerous, using proper lifting tools prevents injury and structural damage.

Various lifting tools

Gardening Tools

Scissors, shovels, and pruning saws support gardening and landscaping tasks. Because plants and soil require precise handling, ergonomic and durable tools improve both safety and efficiency.

Image source: 10 Essential Container Gardening Tools

Major Hardware Tools Classified by Material

Steel Tools

Carbon steel and chrome-vanadium steel tools offer high hardness and wear resistance. Because they can withstand high-impact operations, they are suitable for hammers, wrenches, and other heavy-duty hand tools.

Image source: How Tool Steel is Made and Grouped

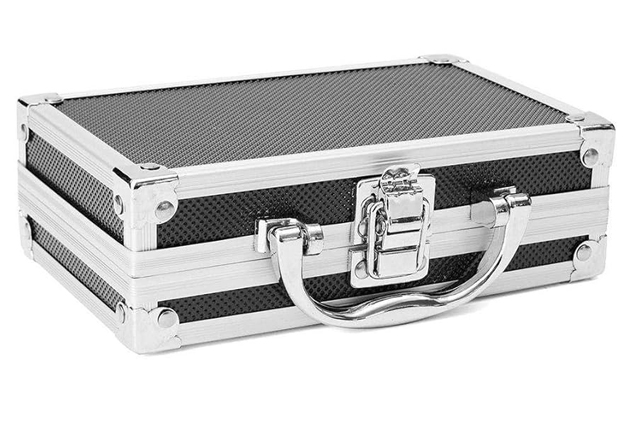

Aluminum Alloy Tools

Lightweight and corrosion-resistant aluminum alloy tools are often used in portable equipment like toolboxes and ladders. Because they reduce fatigue, they are ideal for tasks requiring mobility.

Aluminum carrying case

Stainless Steel Tools

Stainless steel tools resist rust and corrosion. Because they maintain hygiene and durability in damp environments, they are perfect for kitchen knives, surgical instruments, and plumbing tools.

Stainless steel tools

Copper Alloy Tools

Beryllium bronze and other copper alloys produce non-sparking tools. Because sparks can ignite flammable gases or dust, copper alloy tools are essential in hazardous or explosive environments.

Aluminum alloy non-sparking tools

Plastic and Composite Tools

Plastic or composite tools are lightweight and electrically insulating. Because they protect users from shocks, they are widely used by electricians or for light-duty tasks.

Plastic insulated tools

Industry Applications and Market Distribution

Main Production Areas

China's hardware tools industry is concentrated in regions such as Yongkang (Zhejiang), Foshan (Guangdong), and Jiangsu Province. Because these areas have specialized manufacturing clusters, they produce a significant portion of both domestic and export tools. Yongkang is known as the “Hometown of Hardware” due to its extensive production capabilities.

Export Market

China is a leading global supplier of hardware tools. Because European and American markets demand high-quality products, they remain the largest importers of Chinese tools.

Future Trends

As materials technology evolves, intelligent and environmentally friendly tools will gain popularity. Because these innovations enhance efficiency, durability, and sustainability, the hardware tools industry is poised for continued growth and transformation.

Conclusion

Choosing the right hardware tools depends on understanding their application, function, and material properties. Because tools designed for specific tasks ensure safety, durability, and efficiency, selecting the appropriate type—whether manual, electric, pneumatic, or specialized for measurement or construction—is essential. Companies like Dawei Metal provide a full range of tools from hand tools to electric equipment, meeting both industrial and daily-use requirements. By considering the purpose and material of each tool, users can maximize performance and longevity while maintaining workplace safety.