Global Market Expansion

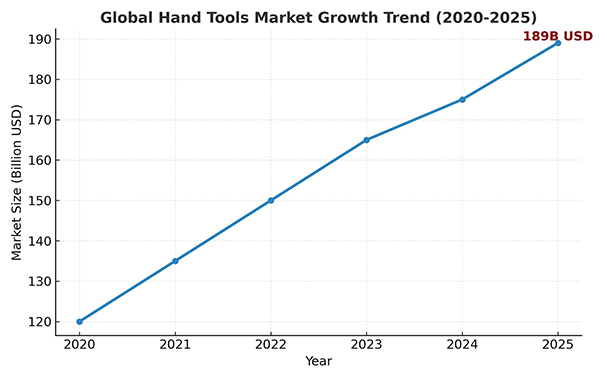

The global hardware tools market is experiencing continuous growth. By 2025, the market size is projected to reach $189 billion, with a compound annual growth rate (CAGR) of approximately 4.3%. China is expected to account for over 30% of global exports, while North America, Europe, and the Asia-Pacific regions remain the core consumption markets.

Segment-wise, power tools hold the largest share at 47%, and smart home tools are growing rapidly, with a year-on-year increase of 15%. The trends toward lithium battery integration and lightweight design indicate that technological innovation is driving the industry toward high-value, intelligent tools.

Growth trend of the hardware tools market size

Regional Market Differences

The demand for hardware tools varies significantly across regions due to differences in cultural habits, consumer preferences, and regulatory environments:

· North America: A thriving DIY culture fuels demand for torque wrenches and other innovative tools, with orders growing 30%. Consumers favor convenient, multifunctional hardware tools.

· Europe: Strong environmental awareness drives demand for high-precision and eco-friendly tools, especially in hydrogen and green energy projects.

· Asia-Pacific: Portable and multifunctional tools continue to be popular. Southeast Asia shows high potential, highlighting demand for flexible, cost-effective tools.

Image from Toolbox

Key Industry Trends

Hardware tool manufacturers are pushing innovation through smart technologies, advanced materials, and green manufacturing:

· Smart Tools: IoT-enabled tools allow remote control and real-time data monitoring, boosting production efficiency by about 30% while enhancing the smart tool user experience.

Smart tools are a major trend in industry development

· Material Innovation: Carbon fiber and high-strength alloys reduce tool weight, while 3D printing accelerates customized and personalized hardware tool production.

3D print tools

· Green Manufacturing: Around 75% of companies adopt eco-friendly materials, such as recycled metals, reducing overall carbon emissions by 20% and demonstrating the industry's commitment to sustainability.

Image source: Hardware Industry Transformation and Brand Practice in the Carbon Neutral Era

Market demand is increasingly diverse. Companies leverage big data analytics to provide customized solutions for high-precision industries like aerospace and healthcare. Additionally, tool kits tailored for specific lifestyles, such as rental apartments or automotive maintenance, enhance user convenience and overall experience.

Competitive Landscape and Challenges

The hardware tools industry shows distinct market segmentation:

1. International Brands

Brands like Germany's Wera dominate the high-end market due to superior technology.

2. Local Enterprises

Domestic manufacturers focus on cost efficiency and e-commerce channels, including platforms like Alibaba International, to capture market share.

Key challenges include:

3. Raw Material Price Volatility

Fluctuations in steel and lithium prices increase production costs.

4. Environmental Compliance

Strict EU and US environmental regulations require higher technological standards for exporters.

Future Opportunities and Investment Directions

Emerging markets and cross-border e-commerce are becoming new growth engines. Infrastructure development in Southeast Asia and the Middle East drives demand for basic tools, while online sales are expected to account for up to 45% of revenue, supported by efficient logistics solutions such as DHL Express.

Investment focus areas include:

· Smart Manufacturing: About 60% of companies plan to implement automated production lines, reducing labor costs and improving efficiency.

· Lithium Battery and IoT Tools: Affordable power tool kits under $45 are most popular, indicating strong demand for cost-effective, smart tools.

Overall, the hardware tools industry is shifting from traditional manufacturing toward smart, eco-friendly solutions. Companies must focus on:

· R&D and Innovation: Integrate smart sensors and IoT features to upgrade products.

· Market Adaptation: Design products according to regional preferences (e.g., eco-friendly tools in Europe, DIY-focused tools in North America).

· Supply Chain Optimization: Implement digital management systems to handle raw material volatility and enhance operational efficiency.

By 2030, the global hardware tools market could exceed $550 billion, with China and emerging markets serving as growth drivers. Technological innovation and sustainable development will define the core competitiveness of industry leaders.